A look behind the scenes at Vobra

Before we talked to Arie van der Tempel, Supply Chain Manager at Vobra, he took us on a short tour through the factory, specifically to the production department where Forklift Joe operates.

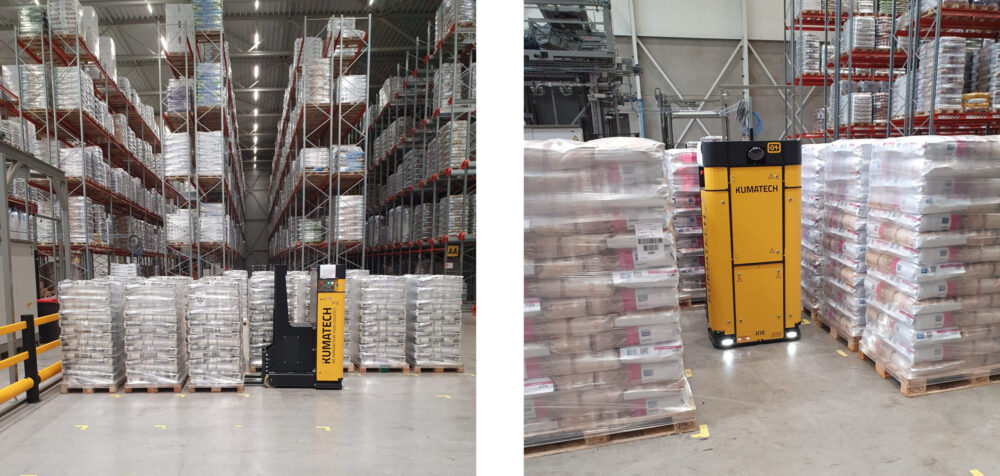

Arie showed us how all finished goods come off the roller conveyor here, so they can be prepared at order level to go to storage or customer. There are tall, deep shuttle racking with a loading bay and roller conveyor from which pallets of bags (small and bulk packages) are delivered from the factory. These are lifted off the roller conveyor and transported to a spot in the loading bay. He shows us with what kind of pallets and customized pallet crates they work and immediately it becomes clear why Forklift Joe is the perfect solution here.

With a clear vision of the future, Vobra is working step by step to optimize and automate its internal logistics.

The company Vobra Special Petfoods

Vobra Special Petfoods is a leading manufacturer of dog and cat foods for customers around the world. The company specializes in premium, super premium and veterinary foods and offers custom solutions as well as larger volumes. Vobra serves a niche market of companies that want pet food produced under private label. In addition, they have their own brands including CaroCroc, SANIMED, CASA-FERA and Impress Your Dog.

Since June 2021, Arie van der Tempel joined Vobra and started managing planning and logistics. Due to several improvement opportunities in the logistics area, the focus is now on logistics. By drawing up a multi-year plan, several logistics processes are being set up more efficiently: “It’s important to know how many places we will need if we are going to run at maximum capacity with the factory. How many people are logistically needed? What can we save in all the repetitive movements we have in our organization?”

Why Forklift Joe?

Automating internal logistics sounds easy, “You have a lot of repetitive movements in a day. Operators who have to get from a spot to the roller conveyor every time with a forklift, then drive the forklift to a square, put down the pallet etc.” An AGV seems like a good solution, but at Vobra, pallets are mainly picked widthways and a lot of work is done with ‘container pallets’, so you have to deal with pallets where the underside is closed just like Euro pallets that come off the roller conveyor widthways and that is an obstacle for most AGV’s. “Vobra really had to wait until the right AGV came out” Arie continues. “Other options, such as a Tractor Tom model with a unit/pallet on it or connecting roller conveyors to each other like in the old factory is too complex for this situation.”

Having heard the name KUMATECH a number of times and having looked at the website several times before, Arie had started looking seriously again. At that time, Forklift Joe just came out and that just might be a good opportunity. He started calling and came into contact with our colleague John Jaspers.

Although the Forklift Joe was still fairly new, Vobra dared to take the plunge. “You have to stay ahead of your competition. If we see it can work, the technology used in it and the machine itself, you pretty much know what you’re getting.” On top of that, in the (pet)food business, quality is an extra important issue, for example, the AGV of KUMATECH looked good quality. Wiring, for example, is well covered and that is an important point in this business.

Together with John and Joris from KUMATECH and their own Technical Department, good conversations were held. “At first, John and Joris even thought that what we wanted was not executable, but we came to an agreement with each other and that makes it extra nice.”

As to the deciding factor, Arie can be very brief: “price, quality and application.”

Support on the shop floor

The intention was to postpone the purchase for a while, but at the same time the limitations of the other truck accelerated the decision to proceed with the purchase sooner. “It is sometimes said that an AGV does not drive fast, but in our case, operators are standing on a truck that does not drive much faster than the AGV.”

A common misconception is that the purpose of an AGV would be to move goods from A to B as quickly as possible. The real purpose, however, is to keep internal logistics processes running smoothly and continuously, without interruptions. By operating in a safe and constant manner, an AGV keeps processes running efficiently.

Furthermore, Vobra believes it is important to include people in its choices, to work with it first and to be envolved during the implementation. “If you don’t run into challenges, you have a special company” Arie says with a laugh.

Implementation and vision for the future

The implementation was quick, and therefore overwhelming. “With small actions you can keep an AGV running well, but an AGV is completely new to us. You don’t know how it works at all despite the instructions. There is a bit of fear of failure, what happens if I do this? We were able to contact Joris with our questions and he was very helpful and explains well.” The training a few weeks later provided a lot of clarity and was enjoyed. “You get a lot more self-confidence from that, afterwards it might have been better to do the training before implementation.”

Specifically, Vobra already sees the benefit of preventing a lot of damage and mess (such as wood splinters) on the shop floor with an AGV. For the future, he emphasizes the importance of thoughtful layout of pallet locations and coordinating routes with logistics personnel. He sees plenty of opportunities for further optimization and automation and is determined to take further steps in this regard.

In conclusion, we asked Arie for a valuable tip for companies considering implementing an AGV. His advice: “Analyze well where the repetitive logistics actions are in your process, especially the logistics movements. When you can have those tasks performed by an AGV, you make it a lot easier to yourself.”