Navigation

Recognition based on floor structure

No constructional adjustments required

Through our unique navigation system, our AGVs recognize their route based on floor structure, eliminating the need for constructional modifications to the building. This makes implementation fast, easy and cost effective!

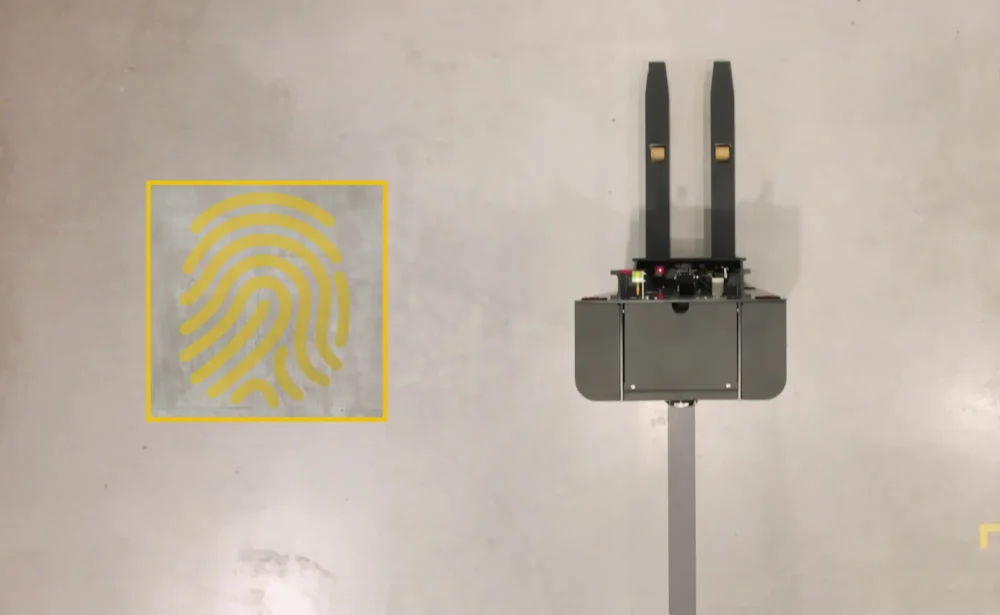

The built-in floor scanner records the floor structure. With our own uniquely developed software the AGV can follow its routes by the recordings. A virtual line is created, a flexible and cheaper alternative to induction lines.

The route is mapped out with the customer beforehand, but can be adjusted on the spot and can easily be extended or adapted later.

Unique floor structure

Like a fingerprint, each floor is unique due to its original and dynamic properties. Especially if it is a concrete floor or any other surface in a manufacturing environment. This makes it possible for our AGVs to follow a recognizable virtual line.

Are you unsure if your floor is suitable for a KUMATECH AGV? Then feel free to contact us!

Own software

Our in-house developed virtual line tracking software makes our navigation method unique and very accurate!

In addition, we listen carefully to our customers and continue developing.

Safety is our priority

In a working environment where man and machine work side by side, safety is very important. Our AGVs are equipped with safety sensors. They detect objects in the environment and the AGV adjusts its speed and stops immediately if necessary. Warning sounds and flashing lights alert to this.